Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 984 All Categories

- 3 Picture Posting and Resizing

- 57 New Member Introductions

- 119 Off-Topic Forum

- 4 Photography

- 2 Resources

- 17 New Product Information

- 168 The SierraWest Forum

- 10 Brett's Blog

- 119 General News & Ramblings

- 3 Re-Release Information

- 6 Q & A about SierraWest

- 9 What Would You Like to See?

- 402 Builds

- 143 HO Scale Builds

- 177 O Scale Builds

- 62 Finished SW Build Pics

- 15 Miscellaneous Builds

- 194 Techniques

- 19 Working with Wood

- 23 Painting Castings

- 5 Masonry

- 23 Scenery

- 37 Tools and Supplies

- 21 Layout Planning & Building

- 40 Miscellaneous

- 24 Prototype Information

- 22 Reference and Research

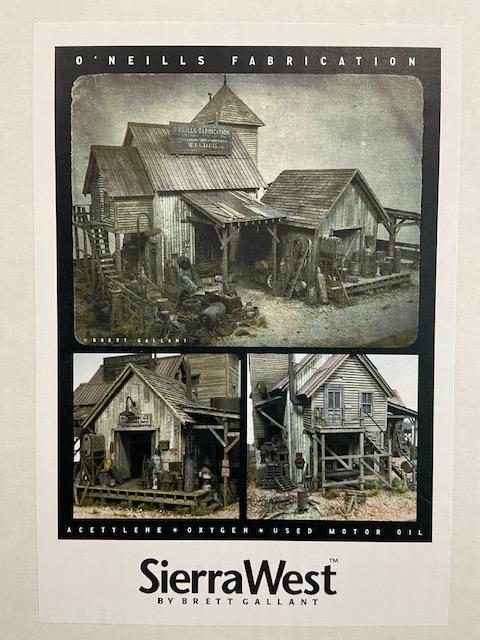

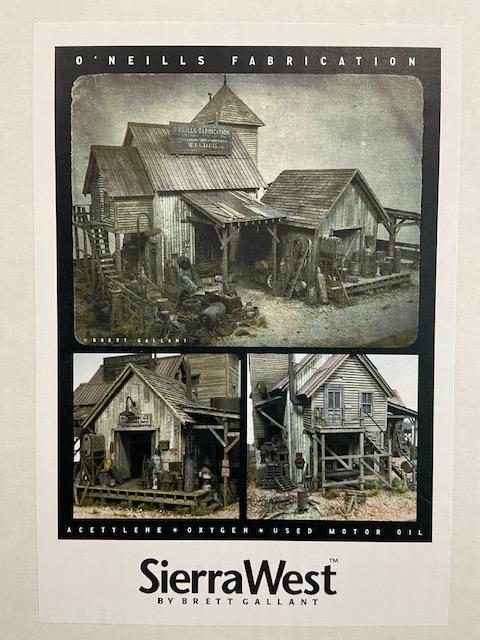

O'Neills Fabrication - HO Scale - An in-depth tutorial for building SWSM kits

Catchy title isn't it??

I was introduced to SWSM kits when I bought an already-built Duluth Plumbing at a train swap meet. I had built a few small kits but I was amazed at the detail of Duluth. How did they do that? I did some research and found the SWSM website. More importantly, I found Karl Allison's tutorials, "Painting Those Details - the Basics" and "Advanced Painting and Weathering of Details with Kevin O'Neill." I was hooked because Karl convinced me through his tutorial that I was very capable of achieving the same results without a lot a natural crafting talent. I bought the Woodcutter's Shack and the rest is history.

I have now built three SWSM kits and I am very proud of the results. I'm not as good as Karl, Brett, Ken Karns, Bill Obenauf, Mike Engler, Steve Drees, or Alan Hubbard, but I believe I can build a pretty good kit by just following Brett's instructions, reviewing the forum build, and asking questions of the resident experts.

Now it's time for me to give back. I talked to Brett about my idea of an in-depth tutorial of a build and he liked the idea. He just said, stay consistent, and don't take two years to build the kit. LOL I'm on it Brett!!

I decided to build O'Neills Fabrication for three reasons. First, it's a kit that is currently available to purchase in case you want to build your kit along with me. Second, the kit incorporates Brett's latest techniques. Finally, it's a really cool kit and is loaded with great details.

As I build the kit, I will go into great detail, mostly with pictures, of each step. I will explain how I do things, which may vary from how you do things. My methods are certainly not the best ones, but they are methods that are tried and true and get great results. I will also give you the details of the tools and other art supplies I use. I will also give you practice tips, sometimes I may give you homework!!

So, here we go ......

The project is - O'Neills Fabrication, a great HO Scale kit.

Home Work:

1. Locate your O'Neills kit and remove from your shelf (remove the dust if necessary).

2. If you don't have the O'Neills kit, get on the website, https://www.sierrawestscalemodels.com/ and order the kit. You have time.

3. Review the video, "Adding Details to Stripwood," which can be found on the website under "University", then "Videos." It's the first video.

4. Find Ken Karn's forum build of O'Neills, which can be found on the website under "Forum,", then "Categories," which is found on the left side, then "HO Scale Builds." Ken's forum build is towards the bottom of page 1, entitled "HO Scale O'Neills Fabrication Official Forum Build." Review the build to get an idea of what we are getting into.

5. Most importantly, commit to building this great kit with me.

Next time, we'll get into the box and start our preparations for this great build. I sure hope you follow along. Phil

I was introduced to SWSM kits when I bought an already-built Duluth Plumbing at a train swap meet. I had built a few small kits but I was amazed at the detail of Duluth. How did they do that? I did some research and found the SWSM website. More importantly, I found Karl Allison's tutorials, "Painting Those Details - the Basics" and "Advanced Painting and Weathering of Details with Kevin O'Neill." I was hooked because Karl convinced me through his tutorial that I was very capable of achieving the same results without a lot a natural crafting talent. I bought the Woodcutter's Shack and the rest is history.

I have now built three SWSM kits and I am very proud of the results. I'm not as good as Karl, Brett, Ken Karns, Bill Obenauf, Mike Engler, Steve Drees, or Alan Hubbard, but I believe I can build a pretty good kit by just following Brett's instructions, reviewing the forum build, and asking questions of the resident experts.

Now it's time for me to give back. I talked to Brett about my idea of an in-depth tutorial of a build and he liked the idea. He just said, stay consistent, and don't take two years to build the kit. LOL I'm on it Brett!!

I decided to build O'Neills Fabrication for three reasons. First, it's a kit that is currently available to purchase in case you want to build your kit along with me. Second, the kit incorporates Brett's latest techniques. Finally, it's a really cool kit and is loaded with great details.

As I build the kit, I will go into great detail, mostly with pictures, of each step. I will explain how I do things, which may vary from how you do things. My methods are certainly not the best ones, but they are methods that are tried and true and get great results. I will also give you the details of the tools and other art supplies I use. I will also give you practice tips, sometimes I may give you homework!!

So, here we go ......

The project is - O'Neills Fabrication, a great HO Scale kit.

Home Work:

1. Locate your O'Neills kit and remove from your shelf (remove the dust if necessary).

2. If you don't have the O'Neills kit, get on the website, https://www.sierrawestscalemodels.com/ and order the kit. You have time.

3. Review the video, "Adding Details to Stripwood," which can be found on the website under "University", then "Videos." It's the first video.

4. Find Ken Karn's forum build of O'Neills, which can be found on the website under "Forum,", then "Categories," which is found on the left side, then "HO Scale Builds." Ken's forum build is towards the bottom of page 1, entitled "HO Scale O'Neills Fabrication Official Forum Build." Review the build to get an idea of what we are getting into.

5. Most importantly, commit to building this great kit with me.

Next time, we'll get into the box and start our preparations for this great build. I sure hope you follow along. Phil

Comments

Terry

I will be joining you. Always something to learn from others. Great initiative Phil.

And yes I am a second-generation HO builder. Not too much time for it lately though, what with two toddlers in the house. But there is time.

In the box you will find the following in addition to the manual:

1. Templates

2. A black sheet of paper

3. Castings - both resin and white metal

4. A separate cylinder casting, which is the tower

5. Four packages of strip wood

6. A bag of wire and styrene

7. A Miscellaneous bag

It is very important that you keeps items in their original bags. As an alternative, you can get some large ziplock bags and transfer the contents of each bag into them for easy access as you need it. Keep the labeling as well for easy identification.

The next step is to read the instruction manual from cover to cover before you do any building. As I read each page, I like to look at the referenced template or item to make sure I'm familiar with each item and its use.

The instruction manual is not just a step-by-step instruction on how to build O'Neills. It is also a great reference manual. In addition to the steps, the manual contains the following:

1. Advance Preparations

2. Essential and Useful Tools

3. General Instructions on the treatment of metal castings and weathering of the wood using fine art sticks

4. Texturing and coloring of stripwood

5. Scenery techniques

6. Supply List

Once you have read the manual, you need to pull the following items from the kit

The acetate sheet and the tar paper can be found in the miscellaneous bag. The foundation castings can be found in the box of castings. We'll get into what we do with these in a future posting.

Next time, I want to give you a tour of my workbench and discuss the necessary tools and supplies.

I'm glad you are following along. Phil

1. A cutting board - this is a smaller one, which I prefer because the larger ones take up too much room.

2. A piece of hardboard - this is where I tape my templates for construction. Using this hardboard, I can easily remove it from the workbench to get it out of the way when I need to do some staining on the glass surface of the workbench.

3. Various brushes - these are the brushes I use the most. We'll get into what kind of brushes later.

4. 2-part epoxy - and absolute must.

5. Toothpicks, swabs, scenic glue, small drill bits, and a sprayer containing 90% alcohol. I use old pill containers for the tooth picks and swabs. I drill a hole in the one for the toothpicks so it will dispense one at a time.

6. CA glue - both thick and thin, paint thinner, and turpentine

7. Collection of Reaper high pigment paints

8. Dropper bottles for AI, 90% alcohol, scenic cement, JAX black, and JAX brass

9. Various paint brushes, sanding sticks, and large tweezers

10. Flashlight - yes, you will drop something on the floor that is very small. This helps in the search.

11. Collection of Diet Coke caps and Gatorade caps, used for gluing and painting.

12. Containers for 90% Alcohol and AI (Alcohol/India Ink)

13. Various tools (we'll discuss each of these as we use them).

14. The Chopper - I used the one offered by Micromark, but it wasn't as precise

15. True Sander

16. Clothes pins, both regular and reversed

17. Cotton cloth (rubbing blackened metal), steel wool, two-sided tape, scotch tape

18. Lighted magnifier, which I purchased at Harbor Freight.

Now, to the drawers below:

1. A collection of Rembrandt high pigment chalks

2. Straight edge razor blades - you can buy them in bulk of 100

3. Small scissors (don't go cheap), droppers, and small tweezers

4. Small bench top grinder with a flexible attachment for polishing and a Dremel

A collection of brushes and makeup brushes

I also have a side cabinet

1. Water reservoir for painting

2. Artist palettes for the various chalks

3. Various weights

4. Various sizes of containers. The ones on the left are used in the blackening process.

5. See next picture

6. Guitar amp - all work and no play makes Jack a dull boy!!! I'm just a beginner, but this is another retirement project.

Finally, my miscellaneous drawer:

Wax Paper - if you don't want to glue right on the template. This preserves the template.

Blue painter's tape

Double-sided tape

Extra tooth picks

Extra clothes pins

3M Transfer Tape

Sandpaper

I hope you enjoyed the tour. I have other items elsewhere, but these are my essential tools and supplies.

Next time, we will start with our advance preparations. Keep reading that manual!!!

Phil

Terry

Thanks again and all the best,

--paul

The first step is to locate and spray paint the loading dock and two foundations a light grey prime color. Here is my steps for doing this.

Locate all the items you need to do this step. I prefer to load the item to be painted on a popsicle stick to help with the painting process. This is the same process I use to paint castings. As for the double-side tape, I use a Scotch carpet tape. I use a carpet tape, especially with heavy castings, because it is super sticky and will hold the casting.

Roll out a portion of the tape and place three popsicle sticks side by side.

Using your exacto knife with a No. 11 blade, trim away any excess tape and separate each popsicle stick.

Here is the final result.

Place the casting on each popsicle stick and press down to make sure it is firmly on the stick.

Using a well-ventilated area, spray paint the castings. I typically use a rattle can spray for this.

The final result. Please note that my spray primer may not be considered "light" grey primer. That's ok. I'm not going to stress about it. The end goal is to achieve a concrete look. As we will discuss later, with chalks and paints, I will be able to achieve this look. This primer color will provide a great base color and act as "tooth" for the chalks.

Go ahead and spray the acetate with Dullcote and the 4X6 paper with black. Don't overspray the paper.

A word about my paint booth, where I do all my painting.

I didn't want to spend a lot of money on a paint booth, so I built this one. It is nothing more than plywood, a bathroom vent, lighting, a power strip, a filter, and a dryer vent. It was very easy to build and gives me a very convenient place to paint.

Most importantly, the booth takes to toxic spray fumes and vents it out of the garage.

Next time, we are going to start texturing and graining the stripwood. I'm very pleased with the attention this blog is getting. Please continue to follow along. Phil

What do we need to do this?

I like to grain wood on the cutting board versus the glass because I found the graining process was doing a number on my tempered workbench glass. In order to grain the wood, you are going to need a steel brush. We could have an entire blog on the various options, but I prefer a tool I bought from Micromark.

You also see an alternative - a plumbers brush that Ken Karns uses. I prefer the Micromark brush because it grains with less pressure and I prefer a little more grain. I would suggest you try both. They are both inexpensive and you may decide to use both depending how much grain you want.

As Brett mentions in the manual, only grain in one direction. I do this for the right half, turn the cutting board around and do the other half. I then slide the boards down and flip them over and do the other side.

Once you are finished graining, you need to get rid of the fuzzies and splinters. Take each individual pieces and run it through your 000 steel wool. Do this very lightly and turn the piece around to get all surfaces. Avoid too much pressure or you will lose all that beautiful grain you just put on the wood.

Once you use the steel wool, it time to put some extra features on the wood. I typically only put knot holes in the wood, but I do this sparingly (2 knots per board). I also prefer the toothpick method.

Take your exacto know with a No. 11 blade and using the point, create a small hole by twirling your exacto until the blade barely comes out the other side. Of course, the bigger the hole, the bigger the knot, but in HO, the knot shouldn't be that big.

Take a toothpick, that has been broken in half, dip the tip in some glue, and insert into the hole you created. Again, stop when the tip of the toothpick just pokes out the other side.

Once the glue is dry, I use a Xuron clipper to cut the excess toothpick. Make sure you cut it as close to the board as possible. As an alternative, Brett suggests a straight nail clipper that can be purchased at a drug store.

It's a bit hard to see, but I have produced a very believable knot hole. Once you stain the wood, the knot hole will be easier to see.

For more information on graining and adding features to the wood, go the the Sierra West website, click under "University" and "Videos" and watch "Adding Details to Stripwood. For more advanced techniques, go to the Sierra West Forum, click on "Working with Wood" under "Categories" on the left side and review Ken Karn's wonderful tutorial, "Working with Wood - the Dr. Grunge Advanced Wood Clinic."

A word about the glue I use. I use Canopy Glue, Formula "560". I use this because it dries clear and is very forgiving. One of the biggest errors made by beginners is leaving glue marks. This can distract from your wonderful crafting. BTW, if you look at my first build, the Woodcutter's shack, you will see Brett pointing out very nicely my gluing errors. LOL!!

Practice Tips:

1. When graining, don't overdo it and don't press down too hard - just easy pressure.

2. Not all wood is created equally and I have found that the hardness of each piece varies greatly. Therefore, assuming the same amount of pressure, you will produce more grain in a softer piece of wood than a harder piece of wood. Therefore, let the hardness of the wood dictate the amount of grain. The result will be a great variance from piece to piece, which is a good thing.

3. When adding those wonderful additions such a knotholes, saw banding, etc., too much of a good thing turns into a bad thing. Always add features sparingly.

Homework:

1. Go to the Sierra West website and review the video, under "University", "Weathering scale stripwood with artist chalk."

Next time, we will stain all the wood you grained. So, get busy, and start graining all that wood!!

Phil

Therefore, I decided to basically hold a virtual workshop and take any interested modeler through the process of building a SWSM kit. And trust me, it's a pleasure for me to do it and a lot of fun. It's also making me pay more attention to my modeling skills.

I use a slight variation on your brushing, I give a pass with a very stiff brush then a pass with a lighter brush. Not sure if the thickness of HO boards would be appropriate for the stiff brush as much though.

Terry