Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 924 All Categories

- 3 Picture Posting and Resizing

- 54 New Member Introductions

- 112 Off-Topic Forum

- 4 Photography

- 2 Resources

- 16 New Product Information

- 166 The SierraWest Forum

- 9 Brett's Blog

- 117 General News & Ramblings

- 3 Re-Release Information

- 6 Q & A about SierraWest

- 9 What Would You Like to See?

- 362 Builds

- 131 HO Scale Builds

- 155 O Scale Builds

- 59 Finished SW Build Pics

- 12 Miscellaneous Builds

- 187 Techniques

- 19 Working with Wood

- 20 Painting Castings

- 5 Masonry

- 23 Scenery

- 36 Tools and Supplies

- 21 Layout Planning & Building

- 38 Miscellaneous

- 24 Prototype Information

- 22 Reference and Research

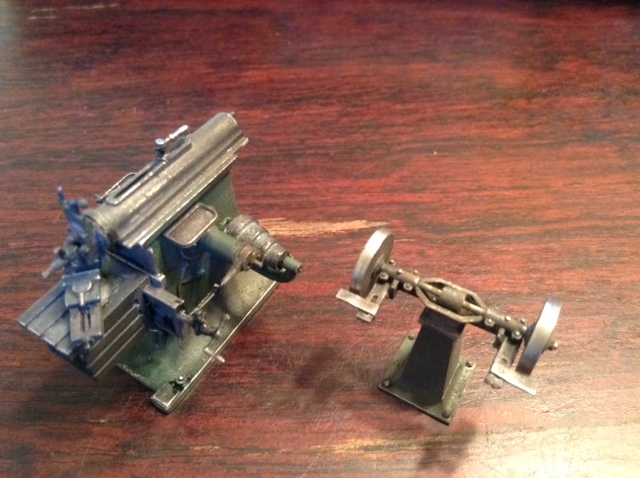

Machinery - O Scale

over christmas needed a small project between holiday activities so built the planer and grinder. Now, these are original CHB kits which I got from a retailer, but they are identical to the SW kits so i felt it was ok to post here. Even in O scale these are small details but so finely cast and designed they go together very easily. The only trouble I had was mounting the rest arms on the grinder- as one can see they need a bit of tweaking.

These are to go into a version of the well documented Sierra RR Machine Shop I've planned out. If anyone else has any builds of the SW/CHB machinery kits it would be great to see them too.

These are to go into a version of the well documented Sierra RR Machine Shop I've planned out. If anyone else has any builds of the SW/CHB machinery kits it would be great to see them too.

Comments

Inspirational.

Karl.A

1 blacken the pieces

2 buff the larger ones (don't try buffing the small ones with a Dremel)

3 paint the areas which would be painted (I airbrushed green with a bit of grey- black in it)

4 chip Or lightly sand painted areas - nuts, edges etc.

5 reapply blackener with a brush in select areas and buff out with a q tip

6 carefully buff handles etc. with a q tip to brighten them. Leave blackener on oily or dirty surfaces (Pax is best for this)

7 float in some black wash for details to pop them out.

8 apply 408.3 chalk ( my preferred fall back dirty dust colour now). Finally dusting once installed.

Of course Chuck D 's ( that's Doan , not the rapper, although u never know what people are into) pieces are phenomenal and probably done in a similar manner.

By the way, I've read that one should only use acrylics on white metal ( unless primed) as minerals will leach through enamels and eventually turn the detail black?..

(Sorry, typed this from my iPad in a coffee shop)....

The Machine Shop is in the middle. It is 60 ft x 40 ft. You can see where the shaper and grinder will go. The Tractor Repair Kit would go on the west end. I'm just eyeballing scale as I don't have dimensions (or kit yet). The northern most rail would go right through the shed to the planer/ radial press in the Machine Shop as it does on the existing prototype today. The next rail would stop at the wheel press, again as per the prototype. A third rail would run along the south side. The south side of the Machine Shop would be opened up (probably leaving off doors) for viewing. A removable roof is a challenge here because of the line and secondary shafts, but essential.

To make the plan super duper evil, the Boiler and Engine House could be added to the east side. However, I don't know if this would be "over powering" the Machine Shop. Historically, it has been run on about 75 HP, by an electric motor since day one. Any comments / insights welcome. At my rate right now this will take me about 50 years...