Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 983 All Categories

- 3 Picture Posting and Resizing

- 57 New Member Introductions

- 119 Off-Topic Forum

- 4 Photography

- 2 Resources

- 17 New Product Information

- 168 The SierraWest Forum

- 10 Brett's Blog

- 119 General News & Ramblings

- 3 Re-Release Information

- 6 Q & A about SierraWest

- 9 What Would You Like to See?

- 402 Builds

- 143 HO Scale Builds

- 177 O Scale Builds

- 62 Finished SW Build Pics

- 15 Miscellaneous Builds

- 193 Techniques

- 19 Working with Wood

- 22 Painting Castings

- 5 Masonry

- 23 Scenery

- 37 Tools and Supplies

- 21 Layout Planning & Building

- 40 Miscellaneous

- 24 Prototype Information

- 22 Reference and Research

Details Details

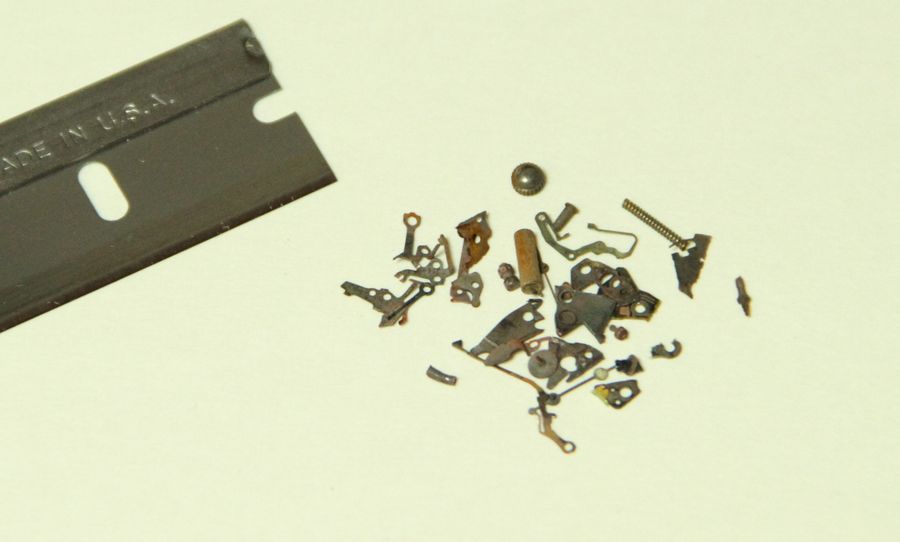

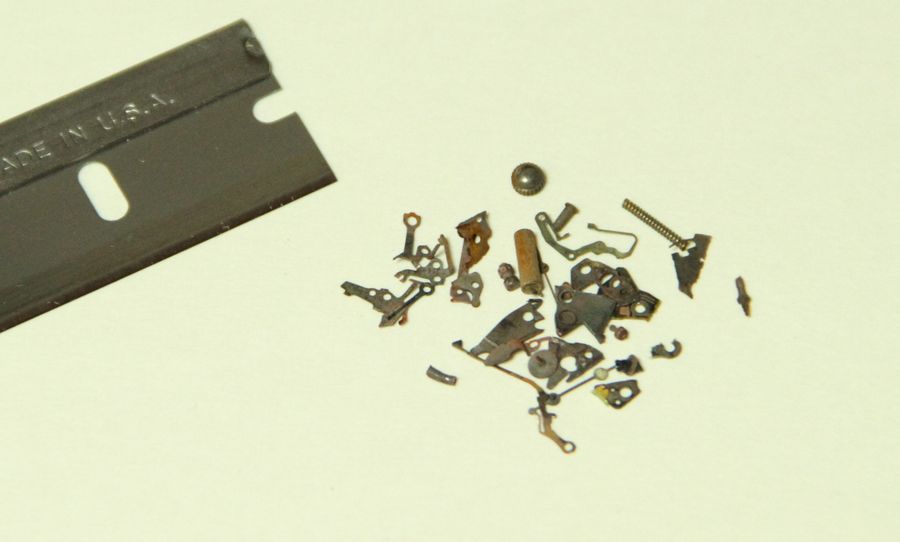

I finally got around to trying something I'd read about in one of the magazines years ago. I picked up a couple old watches at a garage sale for $1. I busted them open and ripped out all the tiny parts, gears, springs and sprockets and even some of the small plastic circuit boards. I used a rail nippers to cut up some of the larger pieces (especially those that were easily identified as a watch part or a circuit board) and dropped them into a cup with some Blacken-it. After sitting over nite, I rinsed them with water and sorted them into 2 piles: big and small pieces. These parts make great filler items for those empty boxes that Brett includes in all SW kits.

I lined the bottom of the boxes with the larger parts and used the tiny pieces on top. In this extreme close up, you can tell the gray piece on the left is plastic and some of the white gears in the right-hand box also look a bit like plastic. However, at a normal viewing angle, those clues disappear and you get a collection of non-descript "stuff" with subtle color differences:

Sometimes just repositioning the boxes makes the the plastic-look fade as well. (Looks like the glue isn't all the way dry yet from this angle.)

I lined the bottom of the boxes with the larger parts and used the tiny pieces on top. In this extreme close up, you can tell the gray piece on the left is plastic and some of the white gears in the right-hand box also look a bit like plastic. However, at a normal viewing angle, those clues disappear and you get a collection of non-descript "stuff" with subtle color differences:

Sometimes just repositioning the boxes makes the the plastic-look fade as well. (Looks like the glue isn't all the way dry yet from this angle.)

Comments

The press works very well, but you will need a good vice or clamp type setup to hold your castings rigidly. Also, you will need to make sure that your drill is sharp, this will reduce the chance of breaking it in the casting. Also a little lubricant will help the drill to stay centred in the hole properly. Greg

John

:~)

John