Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 920 All Categories

- 3 Picture Posting and Resizing

- 53 New Member Introductions

- 111 Off-Topic Forum

- 4 Photography

- 2 Resources

- 16 New Product Information

- 165 The SierraWest Forum

- 9 Brett's Blog

- 117 General News & Ramblings

- 3 Re-Release Information

- 6 Q & A about SierraWest

- 9 What Would You Like to See?

- 361 Builds

- 131 HO Scale Builds

- 154 O Scale Builds

- 59 Finished SW Build Pics

- 12 Miscellaneous Builds

- 187 Techniques

- 19 Working with Wood

- 20 Painting Castings

- 5 Masonry

- 23 Scenery

- 36 Tools and Supplies

- 21 Layout Planning & Building

- 38 Miscellaneous

- 24 Prototype Information

- 22 Reference and Research

Single Cylinder Mill Engine # ME-812

Hi Everyone,

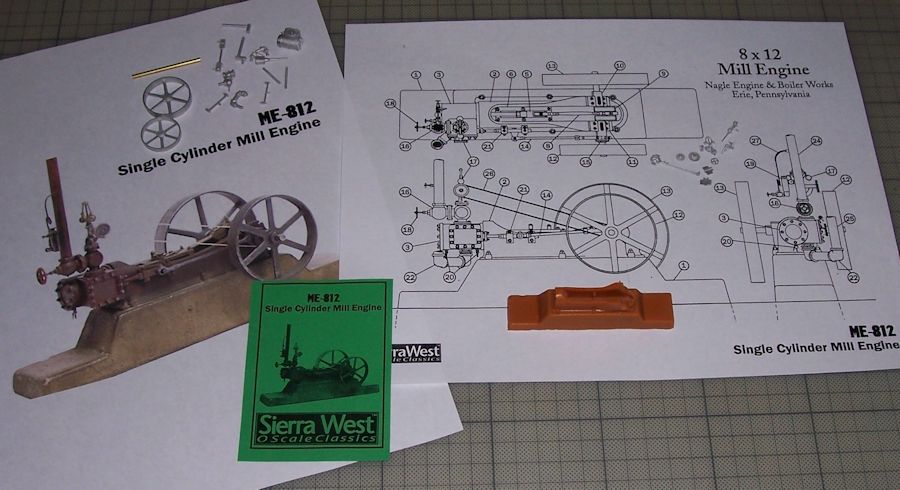

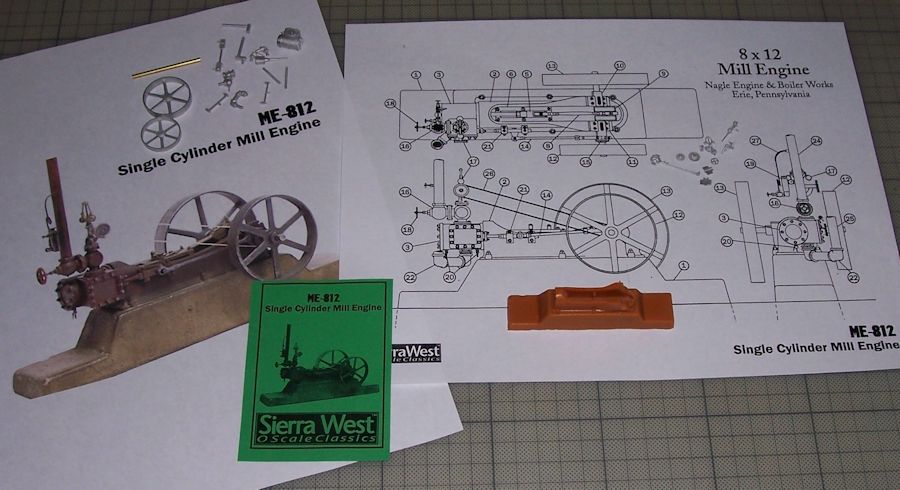

I’m just about to start my build of this mill engine so I thought I’d try to do a SBS as I go along. I say try as I often get so involved in the build I forget, or just don’t want to stop and take pictures so the thread becomes incomplete. I hope to do better this time. This is a real gem of a kit and I will be taking my time with it.

Ok so to start things off here is the obligatory “what’s in the kit” picture. Please note the page on the left is not included with the kit. I wanted a color picture to use in the build so I copied it from the S.W. website http://www.sierrawestscalemodels.com/oscale/boiler.shtml

If you look closely you can see the larger metal parts that come in one bag on the left sheet (upper right-hand corner.) The smaller parts from bag two are harder to see on the right-hand plan sheet. They are between the overhead plan and the front end view. The engine bed and trunk are cast in resin.

First up will be to do some very minor sanding around the base of the resin part, then a light coat of grey (rattle can) primer.

That’s all for now.

Michael

I’m just about to start my build of this mill engine so I thought I’d try to do a SBS as I go along. I say try as I often get so involved in the build I forget, or just don’t want to stop and take pictures so the thread becomes incomplete. I hope to do better this time. This is a real gem of a kit and I will be taking my time with it.

Ok so to start things off here is the obligatory “what’s in the kit” picture. Please note the page on the left is not included with the kit. I wanted a color picture to use in the build so I copied it from the S.W. website http://www.sierrawestscalemodels.com/oscale/boiler.shtml

If you look closely you can see the larger metal parts that come in one bag on the left sheet (upper right-hand corner.) The smaller parts from bag two are harder to see on the right-hand plan sheet. They are between the overhead plan and the front end view. The engine bed and trunk are cast in resin.

First up will be to do some very minor sanding around the base of the resin part, then a light coat of grey (rattle can) primer.

That’s all for now.

Michael

Comments

Karl.A

I'm looking forward to seeing how you do this. What do you plan to use it for?

Respectfully,

John

Thanks for the nice comments.

Bryan, I hope I can come up with some good ideas for myself as well. LOL

John, back in late 2010 into early 2011 A group of modeler (on another forum) myself included all worked on our own versions of a backwoods engine house with a small attached machine shop. The inspiration was a model built by an Australian modeler by the name of Steve Pettit. For myself I finished the main structure but stopped short of doing the planned interior/exterior details. After a few years of accumulated dust I've re-started the project. The mill engine will power about four machines in the small shop.

Michael

Progress update:

I took a spray can of automotive grey primer and shot the resin piece. After allowing a few days to dry I was ready to start adding color.

Before I get into things I’m going to climb up on a very low soapbox to talk about colors and their names. I’m always amused when modelers (sometimes myself included) get so hung up about the name on the bottle. The great ‘Driftwood’ debate seems never ending. It has been at least 15 yrs. since floquil offered this product and yet ‘some’ still look upon it as the Holy Grail.

Ok, (climbing down from my soapbox) as I progress through this build I will give the names of the colors used, more as a reference than anything else. As everyone sees colors in a different way let your eye be the judge.

I chose to take a different path for coloring the throat or frame of the mill engine from Brett’s suggestion of 80% grimy black and twenty 20% boxcar red. Some years ago Karl Allison (KarlA) did the SWSM twin cylinder mill engine in a dirty green. It looked really good to my eye so I chose to go that way. Since then I’ve seen more than a couple of mill engines done in green. If I’m not mistaken Karl used a color called “Christmas Green”. He can correct me if I’m wrong. No I didn’t have that color, and no I didn’t run out to the local craft store to find some. I chose some of the different greens I had and painted a large swatch of each out on a file card. Once dry I felt “Kelly Green” from Folk Art was a good starting point. I knew I’d be dirtying things up a lot so I tried to keep the green on the lighter side. A word about Folk Art brand paint; it is much thicker than the more common Delta Ceramacoat. I made the mistake of over thinning and had to go back and add more paint.

For the concrete base I chose to mix up my own ‘base’ color. Over the years many different companies have offered their version of “Concrete” and to my eye none of them ‘look’ right. There is no ‘one color fits all’ here. Concrete has many different colors/shades/hues all thrown together. For me, I wanted to start out with a neutral grey. By that I mean a grey that has no other color such as blue, green, yellow etc. in it. The primer color was too dark to use so I mixed up one of my own. I started out with Ceramacoat “Bridgeport Grey” then added Ceramacoat “White.” The mix was somewhere around 70% grey and 30% white. This light grey will allow me to add various colors over the grey and not have it go too dark.

I’m sorry for the less than spectacular photos. Hopefully in the future I’ll do better.

Well…I’ve rambled on way too long here. I know most of the modelers here already know/understand all of this stuff. My hope is maybe some of the newer modelers will find some of this information of use.

Thanks for looking in.

Marty

The color of the indents is simply the (rattle can) primer grey I used in the first step. The second grey was brushed on in a semi-dry brush fashion across the surface. This left the indent color more or less intact. I'm not sure if I mentioned the fact the grey craft paint I mixed up was thinned to allow it to flow better. I find all craft paints have to be thinned. In this case I used "Folk Art Extender." I most often use blue windshield washer fluid. I was concerned that the blue dye 'might' show up in the grey. I'm not sure if this would be the case but I didn't want to risk it. The extender I used is clear.

Michael

Respectfully,

John

I’m making slow progress…but hey it is progress I’ve put together the crosshead, connecting rod and crankshaft assembly. I took great care to make sure the crankshaft and crosshead both pivot easily on the connecting rod. I’m not sure this was important but I feel it will make installation into the engine frame a bit easier. Time will time.

I’m one of those modelers who reads the instructions over and over until I have a clear idea what the manufacture is saying…then I decide if I want to follow those instructions or seek a slightly different approach. In this case I did change things up a bit. Brett recommends using a two part epoxy. It makes sense as this gives the modeler a bit of time to align the parts correctly. I will be using epoxy later on but in the build, but for this group of parts I used Dr. Mike’s Model & Crafters Glue. This is a very thin ACC glue and will draw into joints easily. Great care must be taken to insure the glue doesn’t go where you don’t want it. I used a toothpick to apply the glue. For the crosshead to connecting rod joint a short piece of wire (longer than needed) was pushed through the parts and a very tiny drop of glue applied on one side only. When dry the wire was cut flush and filed smooth, on the other side the wire was cut and filed smooth. Then I made sure the crosshead would fit (inside) the frame.

The crankshaft comes as two parts. One part has the pivot pin which steps down to a locating pin. The second part has a hole to receive the locating pin. I needed to enlarge the hole for the receiving pin just a bit. I wasn’t sure if the hole needed to go all the way through but that is how I drilled it. With the connecting rod and both crankshaft parts assembled, I used a very small amount of the ACC applied to the (outside) drilled opening.

I’m not sure I explained this clearly but I know it took me less time to put the parts together than it did to write this up. LOL

As always questions, comments and suggestions welcome.

Michael

Thanks for the nice comments. I too get hung up on names from time to time. It is something I'm trying to get away from.

Michael

I got a chance to snap a few pictures (with new camera) of where I'm at. Some weathering has been applied to the concrete base and engine frame.

As always question, comments, and such welcome.

Michael

Marty

Thanks for the kind words. That is the look I'm aiming for; well used but well maintained. There is a great temptation to rust her up a bit but I've kept that temptation in check. I'm sure there will be some more grime added before I'm done.

Michael

The coloring of the castings is really well done. Great job! The detail on these castings is really amazing.

Jim

That's disgusting! I can't believe how beautiful your work is . . . everyone except me creates museum quality work then hangs it out here for me to drool over. Seriously though, thank you for doing it and for posting. The large forum has excellent posts but here the information is more concentrated and all posters except myself are wizards so it makes it easy to learn.

Respectfully,

John

First off I want to thank everyone for the nice comments. They really mean a lot.

Bryan: I'm trying to sneak up on it. Under weathering is better to my eye than over weathering. You my friend do a great job with your weathering. I've been watching your work silently for years.

Ken: For weathering in this project I'm using mostly Pan Pastels. The yellow was "Yellow Ochre Shade" #270.3. I applied it very lightly at random then rubbed it into the surface. I'm sure that Rembrandt sticks would do the same.

Jim: The fine details in this kit are a testament to Brett's skill and artistry. The challenge for me is to bring them out. In the end when this piece is placed in its intended location most will be lost to the viewer. I will however have had the joy of building it.

John: Don't run yourself down. I've seen your work. No one starts out being a Master. Heck in so many ways I still consider myself a novice but always looking to raise the bar. It is forums like this that always inspire and teach me new things.

Mike: OMG that's so funny, but not far away from the truth. Some years ago I was talking with a fellow modeler about ways to dirty up window glass. His method was 'spit' and some chalk. We modelers can be really inventive. LOL

Michael

I’ve been able to put some more modeling time in on my mill engine. I think (he says with crossed fingers) that I’ve completed the most challenging part of the build. Installing the crosshead guides, crosshead, connecting rod and crank all as one. I was glad I’d taken the time to ensure that all the parts that needed to swivel did. I worked backwards from Brett’s instructions installing the crosshead guides and crosshead first then gluing the crankshaft into the frame.

Here are a couple of quick snappies. I still have to spend some time learning to use my new camera. The main drive wheel hasn’t yet been glued in place. That and the smaller flywheel will be the very last thing (building wise) I’ll do. I’m thinking I may wait on that until I’ve plumbed the boiler (not yet started) and the engine together and mounted them on a concrete pad.

Thanks for looking in.

As always, questions, comments, and suggestions are welcome.

Michael

I'll try again.

Michael

Is there going to be a belt on the wheel? Is you may want to shine the wheel "tire" part to show it use. Just a thought.

Marty

Karl.A

Bryan the brass looking parts are part of the casting. As I've said before Brett is a true master of creating super fine detail. While my camera skills are not really up to the task the picture below shows just how fine these details are. This is the eccentric, strap and rod.

Yes Marty there will be a belt from the mill engine to an overhead belt system. You are right the wheel still needs to be buffed up. I need to pick up a dremel felt polishing wheel first.

Karl you could not be more right about how finely crafted these machines are. Going in I felt pretty good about my building skills, the challenge I felt was how to paint and weather them. So far I'm pretty happy with the results.

I've gotten to the point where most of the remaining parts are very delicate. I've already broken one of the governor weights (ball) off and had to re-glue it. Talk about fun (not.) I've been on vacation but that all ends tonight. I'll have some time to plan out my next move.

As always, questions, comments and suggestions welcome.

Michael

Michael